Tag: Fleet FYIs Podcast

Business intelligence seems to be one of those buzzwords that companies throw around when talking strategy and future-proofing solutions, but many find it hard to define – at least in a way that makes sense to the masses.

It seems to be one of those things that as you enter the fleet industry – or actually, I should probably say the automotive industry at this point – it’s engrained in you from day one. But what actually is it aside from the collection of data points from a vehicle?

This year at Fleet Forward, I think you could tell that most people were happy to be back at an in-person event rather than virtual. It was amazing to see so many people connecting and re-connecting, catching up with new friends and old colleagues that they haven’t seen in quite some time.

To mark the spookiest, scariest day of the year, we’re bringing you the first ever Fleet FYIs Spooktacular special – Fleet HORROR STORIES. A huge thank you to everyone that submitted ideas for this show – hopefully you enjoy our fun, light-hearted take on the spooky side of the fleet industry.

A fuel card or fleet card is used as a payment card typically for all types of fuels at gas stations or filling stations. Whilst most fleets use these for fuel (hence the name, fuel cards) fleet cards can also be used to pay for vehicle maintenance and expenses at the discretion of the fleet owner or manager.

Lithium-ion batteries are made up of three essential components; the positive and negative electrodes, the cathode and the anode, and the chemical layer known as the electrolyte. The electrolyte is formed of salts, solvents, and additives and serves as what’s called the conduit of lithium-ions between the cathode and the anode.

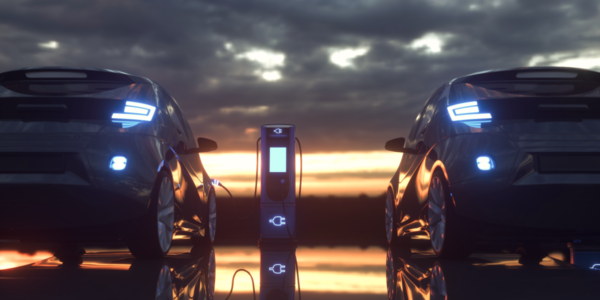

The thing with the fleet industry though, is that we’re in the middle of a massive evolutionary movement for the technology that many of us use to complete our jobs on a daily/weekly basis. Yes, we’re electrifying – no surprise here. But what exactly is the difference between PHEVs and BEVs?

Whether it’s hesitation or logistics – I know there’s a lot of questions surrounding the electrification movement. With any new technology, there are always going to be differences of opinions and potential concerns. And electric vehicles are no different.

Lithium-ion batteries are made up of three essential components; the positive and negative electrodes, the cathode and the anode, and the chemical layer known as the electrolyte. The electrolyte is formed of salts, solvents, and additives and serves as what’s called the conduit of lithium-ions between the cathode and the anode.

Together with the transition to electric vehicles, comes the need for clean, renewable energy sources. It is projected that renewable energy will be the largest electricity source by 2050, as the world moves to completely phase out fossil fuels. With more fleets looking to take on EVs, it is essential to also consider how these EVs are being powered and whether it is a clean, sustainable practice.

We’ll be speaking about electrification, sustainability (as per usual) and the entire movement at it’s core – because I know that sustainability isn’t just for those interested in electrification. There’s a little piece that everyone can take from this.

Lithium-ion batteries are made up of three essential components; the positive and negative electrodes, the cathode and the anode, and the chemical layer known as the electrolyte. The electrolyte is formed of salts, solvents, and additives and serves as what’s called the conduit of lithium-ions between the cathode and the anode.

Working with data is Utilimarc’s bread and butter, the core of what we do here. We’ve been working with one of our partners, GEOTAB, to be able to “unlock” a certain type of data that historically has been harder to access.

The timeframe for electric vehicle technology, infrastructure and innovation has shortened dramatically. It went from a span of 5-10 years being the average to see any major change in innovation, to 1-2 years being the standard.

Getting data where it needs to be continues to prove to be a challenge for many organizations today – especially when it comes to streamlining and effectively optimizing operational strategies.

A lot of the progress that has been made in this sustainability movement has really started to rev up in Europe. The Netherlands, Norway – specifically in cities like Oslo, Amsterdam, London in the UK and even eastern Asia.

As fleets become more sophisticated with the addition of new technology, the need for metrics to evolve also remains consistent. We’re starting with the basics: cost per mile and cost per gallon.

When you look at the amount of major manufacturers that are now talking about changing from gasoline and diesel to electricity, it’s not just the startup companies anymore. It’s actually now large companies General Motors, Chevrolet and Ford that are making the shift.

“They don’t have time to research it and study it. That creates a challenge for adoption. And so for what we do, and knowing lithium-ion, our goal is to make this not so scary. Make the transition simple for our customers, simple for the users. And that’s what we focus on.”

For those of us that like internal combustion engine vehicles, or perhaps we really need them, whether it’s your personal vehicle or perhaps you operate or run a fleet that simply cannot electrify due to lack of vehicle option availability, it doesn’t suit your region or type of work, et cetera, how can we make them to be more sustainable?

The question is, is a reduction of nearly 85% of internal combustion engine emissions worth the initial higher price of this new fuel? Some may say they’re not ready to make the switch.

We all know that understanding your fleet’s data is vital. Especially so as new technologies emerge, and you’re looking to either improve cost efficiencies or implement new programs of acquisition and adoption.

“If you have the data you need in order to be able to report back on it to your user base, then a visualization through a dashboard or a scheduled PDF is a great way to facilitate that behavioral change.”

Range anxiety is a huge issue for fleet operators, drivers, manager and directors – especially when it comes to a new battery technology that has primarily relied on more anecdotal data than real world examples. But, can you blame them?

We’re breaking down sustainability from a new angle – focusing on what exactly makes this new technology sustainable, and whether or not the hunt for materials used to create batteries is as sustainable as you might think.

The Monthly Hotlist will air during the last week of every month, making sure you’re caught up on top stories, new technology launches and new initiatives that’ll surely have people talking.

Understanding your data is a crucial aspect to fleet management. It’s true when you’re growing your fleet, looking to expand, fine-tune your operations and nearly every facet of the management process. Fleet managers know that as their fleets get larger, the data they have grows exponentially – both in quantity and importance. But where does that leave them?

This week on the Fleet FYIs Podcast I’m joined again by the Executive Vice President of Operations for Quanta Services, INC., Dave Meisel, and this week, we’re taking a look at what we can look forward to in fleet this year.

There are a lot of pros and cons to weigh out – whether or not it works for the type of work your fleet does on a daily basis, if your region is suited to hosting an electric fleet (with its current infrastructure) and whether or not your organization is willing to do a deep dive into it’s data to ensure the return on their investment is worth it.

The sustainability and electrification movement is here to stay – and one fleet manager that proves this in his day to day operations is none other than Fleet Manager of the Year award winner for 2020, Mark Stevens.

Your data can tell a story – but it’s not just that it can tell one, it’s how one tells it. In larger organizations, it’s critical to be able to explain data to management at every level from multiple angles.

From the days of ‘software on a shelf’ to the new, streamlined automatic updates of today – we’re covering what’s on the minds of project managers today.

This week, we’re breaking down how COVID-19 is affecting the fleet industry, and how utilization, smarter spending and a shift in mindset might be what’s next for the industry

The fleet industry is in a unique position, having seen other industries begin to adopt this technology, and now adapting it to suit their operations and management strategies.

“If you’re able to quantify the risk of the vehicle being unavailable for the crew when they need it, then the capital investment starts to become very easy to justify…When you’re budget is being scrutinized, it becomes very important to mathematically defend those spare units.”

“Fleets cost organizations so much money, but the ROI of a successfully run fleet can add tremendous value and help build the brand of the organization.”

Fleet FYIs by Utilimarc helps you on the go or behind the desk, making fleet management a little easier. You’ll be able to tune in every week for a new episode on data integration, fleet management – business intelligence style, insightful analysis and all things in between.